The automotive industry seeks innovative solutions for enhancing safety and vehicle efficiency.

This case study explores the use of heat dissipation coatings on automobile tires to mitigate the adverse effects of heat buildup.

Problem Statement

As automobiles operate, particularly over extended distances in hot environments, friction between the tires and road surfaces generates substantial heat. This heat causes vigorous vibration of air molecules within the tire. Due to the viscoelastic nature of rubber, this heat buildup can result in tire bulging, increasing pressure, and heightening the risk of blowouts. Such conditions pose significant safety hazards and can lead to serious vehicular accidents.

How Novota Can Help?

Addressing these challenges requires an innovative solution that facilitates faster cooling without affecting the tire’s performance.

When applied to the tire’s rim, heat dissipation coating reduces overheating by effectively dissipating the heat to the surrounding environment and facilitating faster cooling. During this case study, Novota conducted several in-house and on-field testing.

The effectiveness of coating was tested on varied tire surfaces. Below are the observations on each surface.

Outer Surface of the Tire: The coating did not yield the desired results; instead, the air temperature inside the tire increased.

Inner Surface of the Tire: The coating emitted heat back into the tire, causing increased air temperature.

Brakes: Coating the brakes had no significant effect on tire temperature, as the braking system is designed to manage heat effectively.

Tire rim: Coating on Rims resulted in fast heat dissipation from the tire.

In-house testing was conducted by running the vehicle’s front wheels on fixed cylindrical iron rods to create controlled friction for one hour. The results indicated that the tire with the coated rim exhibited a significantly lower temperature increase than the uncoated tire. This suggests that the heat dissipation coating effectively mitigates temperature rise under conditions of prolonged friction.

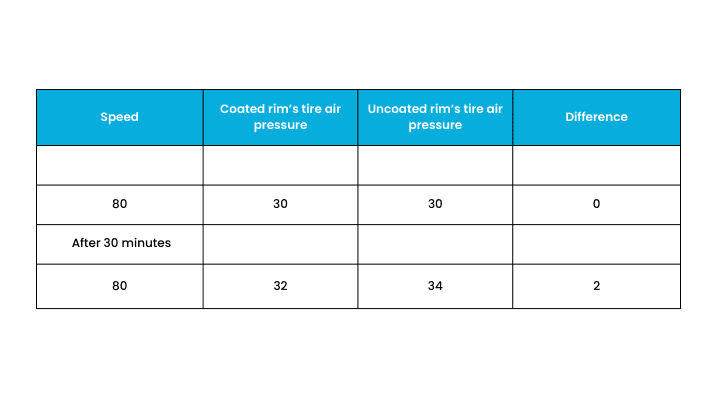

On-field testing: Conducted by operating the automobiles on rough roads in a hot environment for approximately one hour. The results indicated a clear relationship between tire pressure and temperature.

Benefits of Heat Dissipation Coating on Automobile Tires

Applying the product to the tire’s rim yielded favourable results. After 60 minutes at 80 km/h, the coated tire’s pressure increased by only 2 psi, compared to a 4 psi increase in the uncoated tire. This indicates a reduced pressure increase in the coated tire, attributed to the coating’s high emissivity, which enhances heat dissipation.

When the formulation is applied to the rim of the tire

Table 2 (in-house testing)

Table 3 (on rough roads and hot atmosphere testing)

Are you looking to upgrade the safety and performance of your automotive products? Get in touch with Novota to explore our innovative coating solutions tailored to your needs.